Correct assessment of battery test results

This article contains:

Tests of conventional starter batteries (SLI) can be carried out quickly. However, in the case of batteries for start-stop systems, considerably more factors must be considered. We have summarized the meaning of the test results for conventional SLIs and start-stop batteries for you.

Test and assessment of conventional wet batteries

Testing a starter battery only takes a short time. With this common type of battery, simply the determination of the open-circuit voltage provides adequately reliable information about the state of the battery, as with conventional starter batteries, only a powerful cold start current is decisive for full functionality.

Most starter batteries are now maintenance-free. With maintenance-free batteries, there are usually no filler plugs, so that there is no possibility of measurement with a hydrometer. However, the charge can also be measured with a voltmeter or a Multimeter. A fully charged starter battery has a voltage of 12.8 Volt. If the open-circuit voltage drops below 12.4 Volt, the battery needs to be recharged.

Test and assessment of a start-stop battery

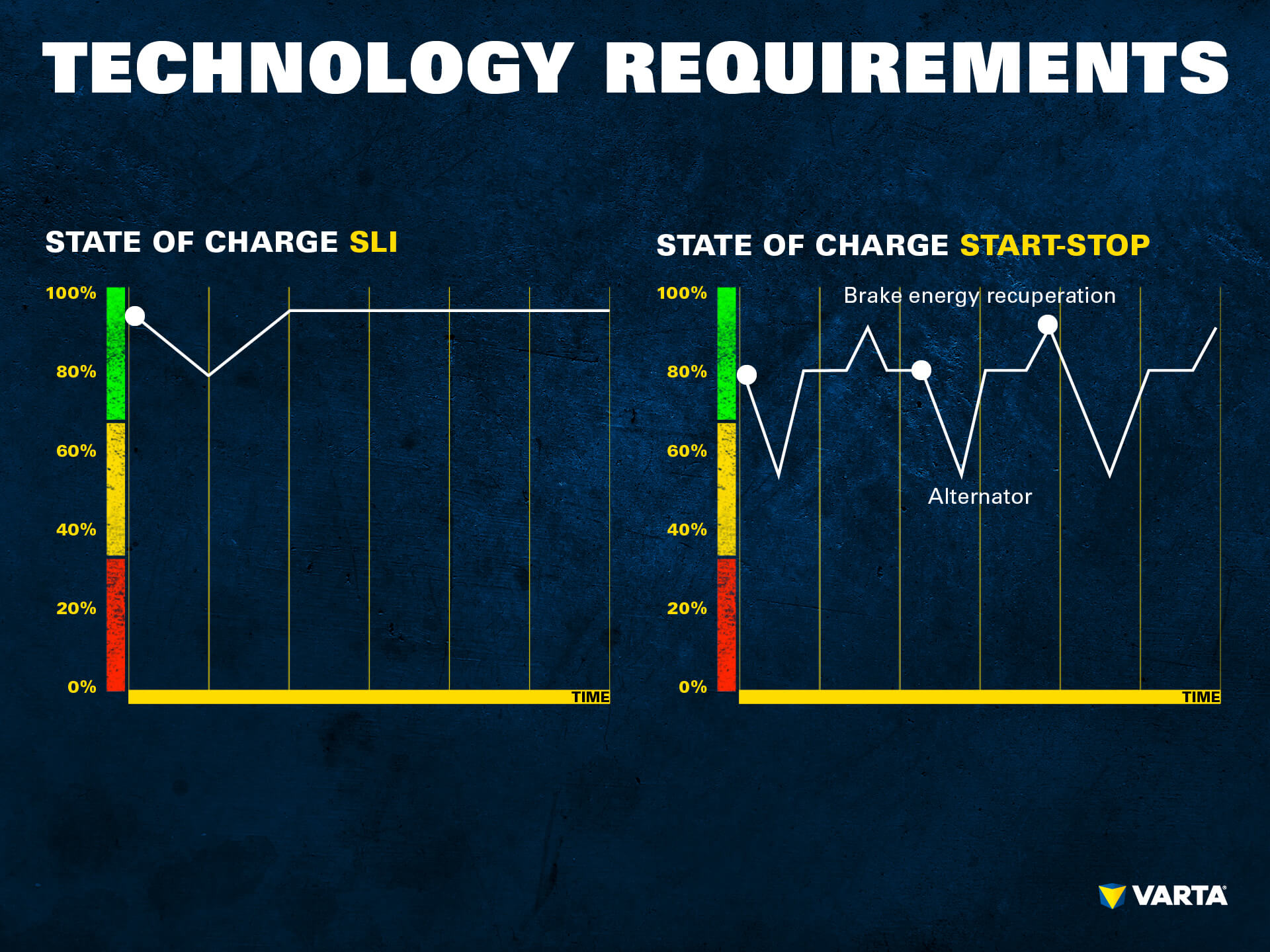

The battery test for an AGM or EFB battery is more extensive, as the demands on these special battery technologies are more complex. These batteries are subject to frequent starting processes and continual partial discharges. This effect is increased by the electrical consumers which have to be supplied by the battery, even when the engine is stopped.

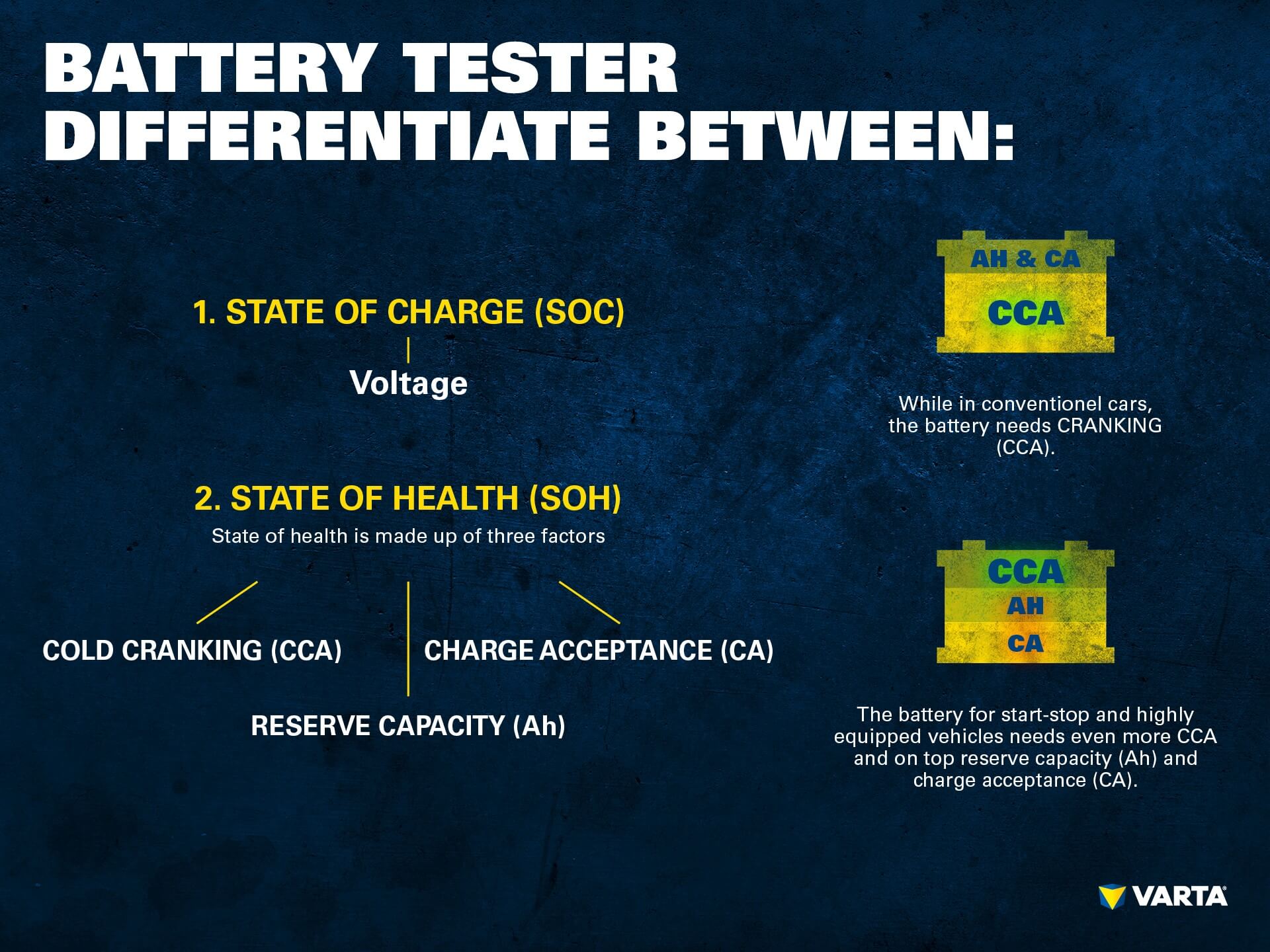

In addition to the state of charge, also known as the “SOC” (“State of Charge”), it is therefore also important to know:

- How much active material is still available for storage of energy by the battery?

- How quickly is the battery recharged after a partial discharge?

With most battery testers, these two questions cannot be answered precisely, because they only measure the cold start current (CCA). The residual capacity (Ah) and charge acceptance (CA) can only be determined indirectly and imprecisely with these battery testers.

Why are the residual capacity and charge acceptance so important for a reliable test result?

For a start-stop battery, good charge acceptance is very important because it needs to supply sufficient current during a journey with a large number of stops and starts: Consumers remain in operation during the standstill and the large number of engine starts also have to be ensured. During driving and braking (in the case of a start-stop system with recuperation, which feeds regenerative energy into the battery) the battery must therefore charge sufficiently in order to reliably handle the next stop.

The residual capacity must be sufficient to also supply the consumers during the standstill. The residual capacity is the energy which is available to supply the electrical consumers during certain situations:

- During all stop phases, either at traffic lights, in traffic jams or when parking.

- To compensate for inadequate charging by the generator, or to maintain a stable voltage while driving.

Workshop recommendations

Interpretation of the test results for a start-stop battery is more difficult than with conventional starter batteries. This applies in particular to test devices with which conductivity measurement is not possible, or battery testers in which no suitable test algorithm is implemented for new battery technologies such as AGM or EFB.

The indication “Battery OK” then apparently shows that the battery is in a good state of health. However, it is often obvious that the battery is reaching the end of its useful life.

In the case of a test result which does not definitely indicate “Battery OK”, other influencing factors must be taken into account for better interpretation of the result. E.g.

- Age of the battery (loss of performance due to aging effects)

- Vehicle mileage with the battery (battery deterioration during operation)

- Previous deep discharge or long standstill period without maintenance charge (damage to the battery)

- Subjective impression by the driver – e.g. fewer start-stop moments than previously. In this case, the Battery Management System (BMS) reduces the load on the battery in order to protect it. This is a sign that it is time for a battery replacement